The Sorane ZA-12 Transcription Arm takes the strengths of the Sorane SA1.2 tonearm (already recognized as a Class A component) and marries these strengths into a purist ‘no compromise’ high-performance tonearm

No compromise meant giving up detachable headshells and lengthening the arm for lower tracking error. While the ZA-12 is 3″ longer than the SA1.2, the total mass of the ZA-12 is lower, guaranteeing that the new arm will be compatible with a broader range of high-quality cartridges. And if you want more mass for very low compliance cartridges, you can easily add it.

Sorane ZA-12 Key Features:

- Lower mass than the SA-1.2

- Detachable RCA phono cable

- Optional XLR phono cable available

Sorane Tonarm Range Shared Features:

CNC, Machine-tooled and hand-assembled by skilled Japanese

craftsmen. This highly skilled and delicate hand-assembly

differentiates Sorane tonearms from mass-produced Japanese

tonearms. With standard quality goals, high-volume production

tonearms are manufactured by die-casting and semi-automatic

assembly line processes, to keep production costs low.

b Concerning the reproduced sound from these models: The

the designer is confident you will get a precise and clean sound,

which can only be had from hand-made tonearms, but at a very

reasonable price.

In particular, the SA-1.2 and ZA-12 will produce rich and tight

bass, coming from the extremely rigid rectangular shaped armwand.

d Skilled hand assembly does not simply mean “combining

the constituent parts by hand”. Skilled hand assembly involves

measurement, adjustment and hand-fitting to produce an optimal

interface between machined surfaces. Once completed, the fitment

between every part is ideal, satisfying the necessary conditions for

chatter-free reproduction of analog sound.

e Most importantly, the key to tonearm quality is highly sensitive

and delicate motion, for which the bearings are the determining

factor.

Gimbal-bearing designs for excellent bass, dynamic sound and

imaging, as well as unconditional azimuth stability (Which is

the biggest problem for conventional uni-pivots bearing).

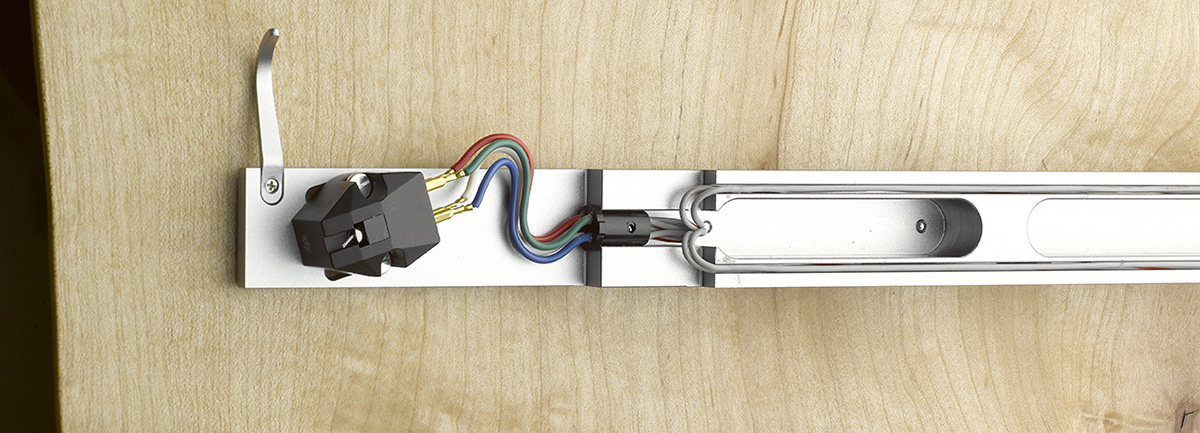

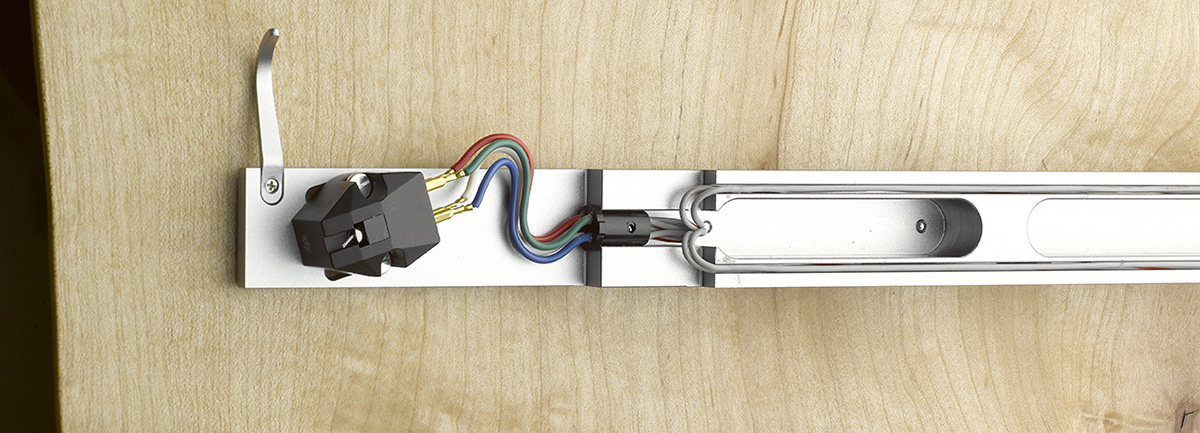

For SA-1.2, SA-1.2B, SA-1.2BCS, (As attached photo) two

sets of fine radial bearings are installed for both horizontal (set

in the bearing stem column) and vertical (further small bearing at

tonearm wand) suspension. This assures audiophiles of smooth

tonearm function, greater longevity, better consistency, and

enhanced ability to track warped vinyl.

(In SA-1.2BCS,negative-balance selection is to follow more

precisely to warped vinyl)

(More versatile bearing of “Double Bearing Pivot suspension” is

applied to ZA-12, as mentioned after.)

h For TA-1 and TA-1L, the same type radial bearing, used in the

SA-1.2 for horizontal motion is used, while a delicate pivot bearing

is employed for vertical movement (this is still a bearing, but the

bearing axis end is cone-shaped and requires careful assembly

and adjustment). The right side cone in this photo is inserted into

the miniature bearing inner race.

For the SA1.2 and ZA-12, lead wires run through separate

aluminium tubes inside the arm, maximizing stereo separation.

For the ZA-12, the tonearm collet is removed. The effective

length and geometry gives very low tracking error. The stylus tip

of the cartridge is maintained as close to the centerline of the

tonearm as possible. The mass distribution is kept as close to

neutral as possible.

Comes with phono cable (RCA output plug, or optionally as

XLR), screws, washers, wrench and marking pin.

l Antiskating mechanism works favourably, in proportion to

cartridge vertical stylus tracking force.